Why Supply Chain Scalability Is the Growth Initiative You Can’t Ignore

May 27, 2025

Supply chain issues used to be operational problems. Now they’re strategic liabilities.

As companies scale, their ability to deliver products or services reliably becomes just as important as what they deliver. In a business landscape defined by volatility, bottlenecks, and rising customer expectations, supply chain scalability is no longer optional—it’s a growth imperative.

The Scalability Gap: A Risk Hiding in Plain Sight

A recent study by McKinsey found that 91% of supply chain executives believe their supply chains need to become more resilient, yet only 17% feel their current systems are capable of handling sustained growth or disruption. That 74-point delta is more than a red flag—it’s a threat to continuity, profitability, and reputation.

What’s more, Capgemini Research reports that businesses lose $184 million annually on average due to supply chain disruptions—through lost revenue, operational costs, and customer churn.

Despite this, many companies continue to operate with single-source vendors, rigid procurement contracts, and outdated forecasting models that fail to adjust for real-time shifts in demand.

What Does It Mean to Scale a Supply Chain?

Scaling a business isn’t just about top-line growth—it’s about the infrastructure that supports it. A scalable supply chain can flex up (or down) based on demand without breaking. It’s capable of absorbing volume spikes, supplier variability, or shipping delays without compromising speed, cost, or quality.

Scalability also requires visibility. Companies need to see upstream and downstream in real-time to make informed decisions about inventory, fulfillment, and risk mitigation. Without that visibility, organizations are reacting instead of planning—and reactionary supply chains rarely outperform.

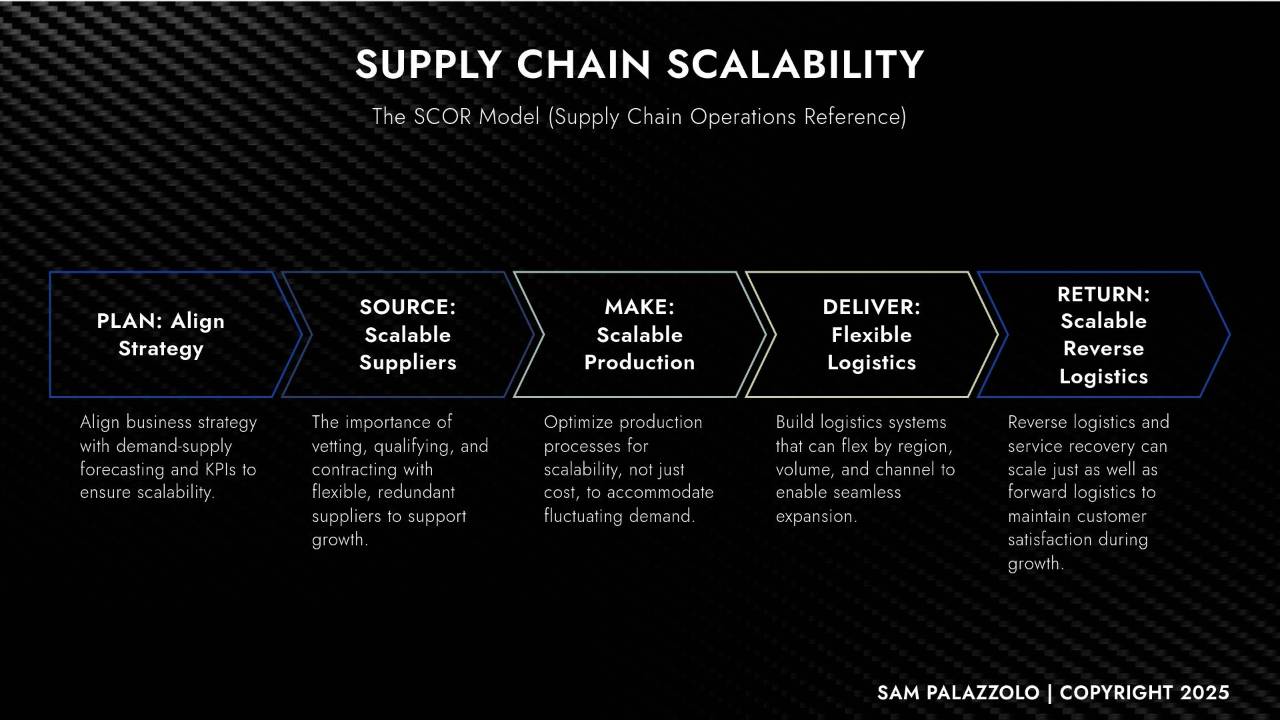

Introducing the SCOR Model: A Strategic Blueprint for Supply Chain Scalability

To address these challenges, many organizations are turning to the Supply Chain Operations Reference (SCOR) Model, a strategic framework originally developed by the Supply Chain Council and now widely adopted by global enterprises and growth-stage businesses alike.

The SCOR Model breaks the supply chain down into five primary areas:

- PLAN – Align supply chain strategy with business goals, demand forecasts, and performance KPIs.

- SOURCE – Identify and manage suppliers who can scale and diversify sourcing to reduce risk.

- MAKE – Optimize manufacturing and production for scalability, efficiency, and flexibility.

- DELIVER – Streamline logistics to accommodate shifts in geography, volume, and channel.

- RETURN – Ensure reverse logistics (returns, repairs, recycling) scale alongside forward operations.

This modular approach provides both a diagnostic tool and an execution roadmap. It allows leaders to benchmark capabilities, standardize processes, and proactively design for growth.

“The SCOR model is used by leading organizations around the world to map, measure, and proactively strengthen their supply chains.”

— SupplyChainPlanning.ie citing HBR

A Lesson from the Field: When Growth Exposed the Gaps

Consider a mid-sized manufacturer I work with that, a while back, expanded into four new markets. Sales surged by 40% quarter-over-quarter, but the company’s supply chain was built for static production and single-region logistics.

As demand grew, production bottlenecks emerged. Their primary supplier ran out of capacity, leading to delayed shipments, overtime costs, and unsatisfied customers. Their reverse logistics—returns and repair management—collapsed entirely under the volume pressure.

Applying the SCOR model, the company conducted a full scalability audit. Within 90 days:

- Supplier redundancy was introduced across three continents

- Production processes were retooled to allow batch flexibility

- A new transportation management system (TMS) added real-time logistics tracking

- A “Return Ready” program standardized processes across service centers

The result? A 20% improvement in order-to-fulfillment cycle time and a 35% reduction in supply chain disruptions. Most importantly, the company regained the confidence to continue its expansion strategy.

Building for Resilience and Growth—Simultaneously

Scalability and resilience are not tradeoffs—they are mutually reinforcing. A well-architected supply chain not only handles growth but also recovers faster from shocks.

According to Bain & Company, companies that invest in scalable supply chains experience 15–25% faster recovery from disruptions and 20%+ gains in customer satisfaction.

Here’s what that looks like in practice:

- Scenario planning and stress testing for high-growth quarters

- Supplier scorecards to measure readiness and capacity

- Integrated technology platforms to enable visibility and collaboration

- Cross-functional governance that aligns supply chain with strategy, finance, and sales

The best time to build this? Before you need it.

Final Thoughts: The Cost of Waiting

Leaders must ask themselves: Can my supply chain scale as fast as my strategy?

If the answer isn’t a confident yes, then you’re sitting on a constraint that will eventually surface—likely at the worst possible time.

Your supply chain is not just an operational engine. It’s a strategic asset. Treat it like one.

Ready to scale your operations with confidence?

- Start with the Catalyst Audit — a diagnostic tool to uncover hidden growth constraints across the Five Pillars of Scale.

- Want to surround yourself with elite operators solving similar challenges? Join the Catalyst Board.Apply now for The Catalyst Board — an invite-only executive circle that accelerates business growth through peer insight and strategic playbooks.

- Need help translating strategy into execution? The Executive Strategy Catalyst Program is where we roll up our sleeves, align your supply chain with your growth vision, and execute with precision.

Sam Palazzolo, Principal Office @ The Javelin Institute

PS – Sign up for the weekly Business Scaling Newsletter at sampalazzolo.com — and build your company’s next chapter on the right infrastructure.

Key Takeaways:

- 91% of supply chain leaders say resilience is critical, but only 17% feel prepared

- $184M/year is lost on average due to supply chain failures

- The SCOR Model (Plan, Source, Make, Deliver, Return) offers a flexible, modular roadmap for scalability

- Real-world success stories prove supply chain scalability is not just theoretical—it drives measurable outcomes

- Building supply chain scalability is a precondition for long-term growth, not a reactive fix

SUBSCRIBE FOR WEEKLY BUSINESS SCALING STRATEGIES

REAL STRATEGIES. REAL SOLUTIONS.

We respect your privacy. Unsubscribe at any time.