Operational Efficiency: The Scalable Advantage Hidden in Plain Sight

May 21, 2025

As organizations pursue growth, they often direct attention to strategy, capital, or market expansion. Yet, more often than not, the real constraint is not ambition—but execution. Scaling a business is less about vision and more about building a system that can deliver consistently as complexity increases. That system is grounded in operational efficiency.

Why Operational Efficiency Is the First Scalability Test

In a 2023 study by The Collective, 70% of scaling companies experienced growth stalls due to operational inefficiencies, not lack of demand or leadership vision (source). Similarly, McKinsey found that organizations that actively invest in operational improvement can see 25% higher productivity and 20% lower operating costs (source).

These numbers aren’t theoretical. They reflect the often unseen impact of flawed processes, redundant workflows, or unaligned resources—issues that silently erode scalability from within.

Having worked inside Toyota/Lexus—arguably the global benchmark in operational excellence—I saw firsthand how attention to process, not just product, determines long-term performance. From supply chain management to customer delivery, operational discipline ensures that ambition converts into execution.

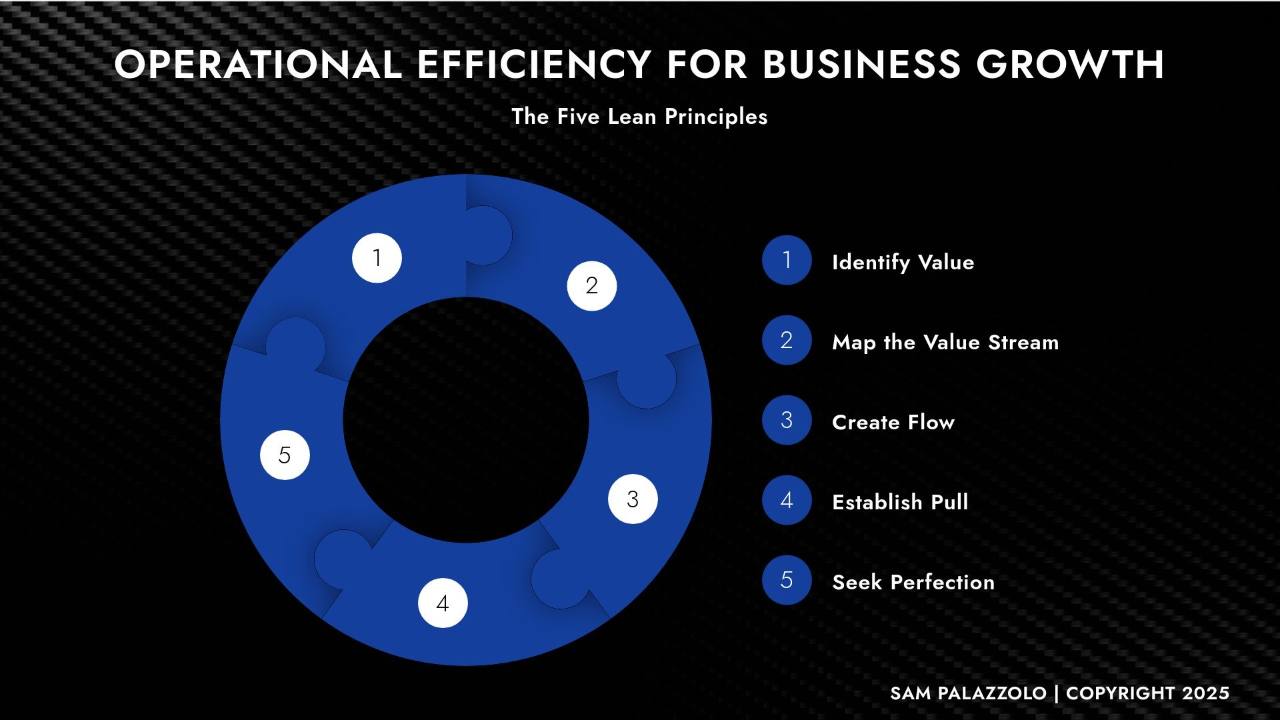

The Five Lean Principles: A Proven Framework for Operational Excellence

One of the most powerful frameworks for driving operational efficiency is the Five Lean Principles, originating from the Toyota Production System. These principles serve not as a project checklist but as a perpetual system of improvement. They provide a model for turning complexity into clarity and action.

1. Identify Value

Efficiency starts with understanding what customers truly value. This isn’t about adding more features or touchpoints—it’s about uncovering which aspects of the offering drive loyalty, impact, and repeat business. Leaders should regularly ask: Are we delivering what matters most, or just what’s easiest to produce?

Case Insight: A B2B services company assumed speed was its differentiator. After customer interviews, it learned responsiveness and problem-solving ranked higher than delivery time. Realigning priorities reduced unnecessary service escalations by 30%.

2. Map the Value Stream

Once value is clear, organizations must trace every step involved in delivering it. This mapping should expose duplicative steps, approval delays, manual handoffs, and underutilized resources. Think of it as an MRI of the operating system—necessary to diagnose operational pain.

Example: One firm with a 10-step onboarding process discovered that three steps were performing redundant ID verification. Post-realignment, the process went from 15 days to 7.

3. Create Flow

Flow is the antidote to operational friction. This principle ensures that work progresses smoothly through the system without bottlenecks. It requires coordination between teams, real-time visibility, and the elimination of “dead zones”—those gaps where handoffs stall and accountability diffuses.

From Experience: At Toyota, reducing flow disruption was often less about speed and more about design. A single tool placement adjustment on an assembly line saved hours over a week—proving that micro-efficiencies often create macro-impact.

4. Establish Pull

Rather than pushing production based on assumptions, organizations should “pull” resources based on customer demand. This reduces overproduction, inventory costs, and misaligned effort. Tools like Kanban help, but mindset matters more: build what is needed when it’s needed.

Client Scenario: A tech startup overstaffed product builds based on forecasted demand. Transitioning to a pull model tied to live pipeline activity reduced overhead by 22% without impacting delivery timelines.

5. Seek Perfection

Lean is not a one-time event. It is a continuous journey that prioritizes feedback loops, frontline empowerment, and small but frequent process enhancements. Perfection is never the goal—but the pursuit ensures constant adaptation.

Leadership Note: The most scalable companies are those where every team member—regardless of level—feels responsible for improving how things work.

Operational Efficiency Is a Leadership Lever

Operational efficiency isn’t the COO’s problem or a back-office concern. It is a strategic lever. When a business can repeatedly deliver value without delay, rework, or friction, it creates capacity to grow—without inflating cost structures or burning out talent.

Leaders who invest in operational maturity often report:

- Reduced customer churn due to consistency

- Faster cycle times, leading to earlier revenue recognition

- Clearer accountability, reducing internal conflict

- More confident forecasting and planning

In today’s uncertain markets, these are competitive advantages—not administrative wins.

Closing Thoughts: Build the System Before You Scale

Organizations that scale well do one thing right before anything else: they operationalize excellence. Whether you’re in manufacturing, services, SaaS, or professional consulting, the discipline of Lean—and the operational clarity it delivers—builds a foundation that growth can stand on.

Efficiency isn’t about doing more with less. It’s about doing what matters—with precision, alignment, and purpose.

Want to Scale Smarter?

If you’re ready to eliminate execution friction and embed systems that scale:

Sign up for the Business Scaling Newsletter

Receive weekly strategy, operations, and leadership frameworks for real growth: https://sampalazzolo.com

Sam Palazzolo

Real Strategies. Real Results

Key Takeaways

- Operational efficiency is often the hidden constraint behind stalled growth.

- 70% of growing businesses experience slowdowns due to inefficiencies—not lack of demand.

- The Five Lean Principles (Identify Value, Map the Value Stream, Create Flow, Establish Pull, Seek Perfection) provide a repeatable system to scale execution.

- Operational improvements directly impact cycle times, profitability, and customer experience.

- Efficiency is not a backend concern—it’s a front-end strategy enabler.

- Leaders must prioritize process design as much as product design to scale with confidence.

SUBSCRIBE FOR WEEKLY BUSINESS SCALING STRATEGIES

REAL STRATEGIES. REAL SOLUTIONS.

We respect your privacy. Unsubscribe at any time.